下面小编根据专业资料向大家介绍一下粘合的基础知识

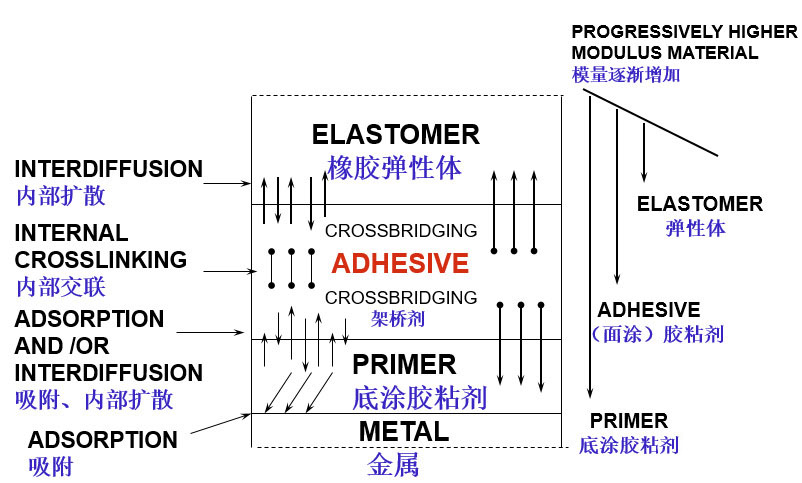

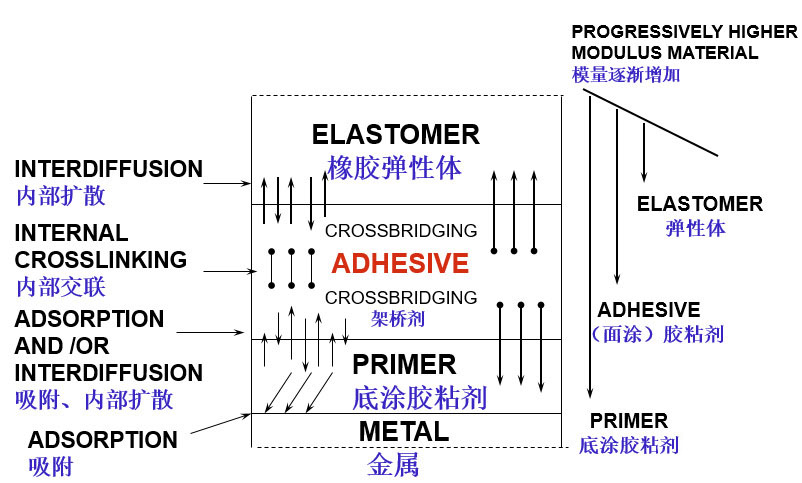

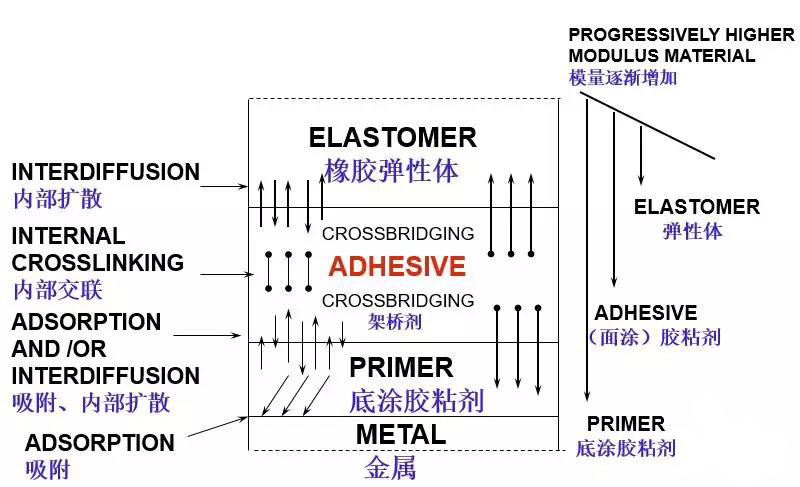

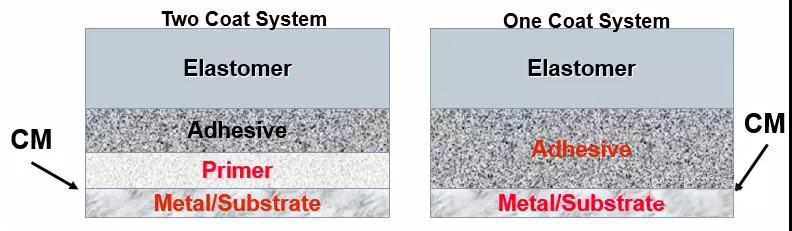

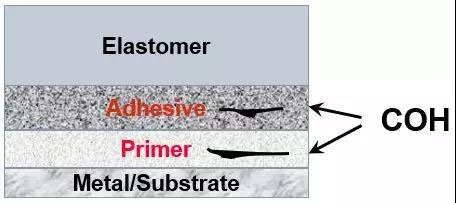

Mechanisms ofBonding:

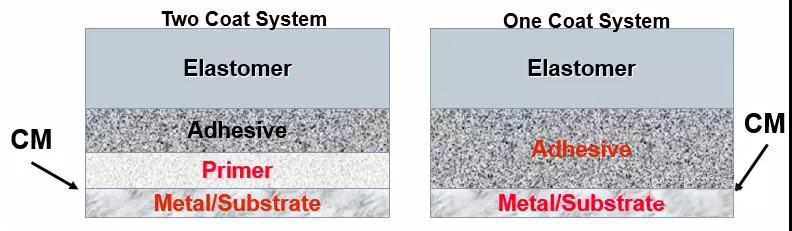

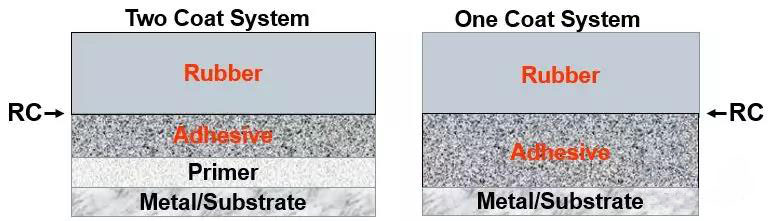

Two Coat System

双涂胶粘剂粘结机理

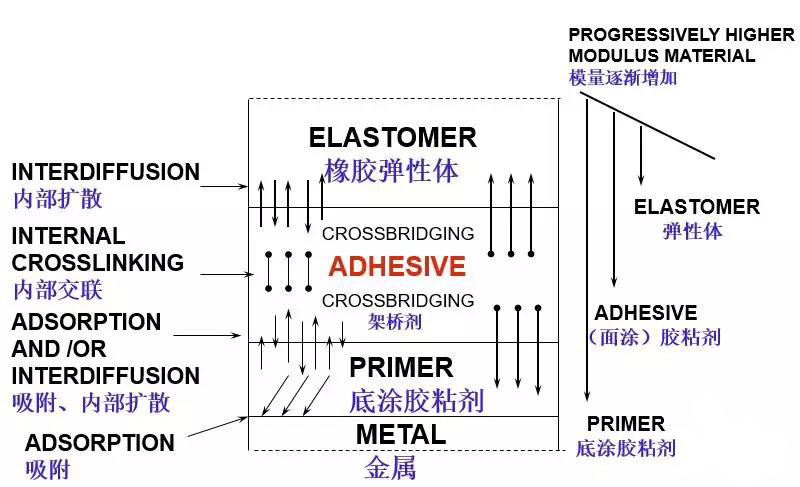

Mechanisms of Bonding:

One Coat System

单涂粘结机理

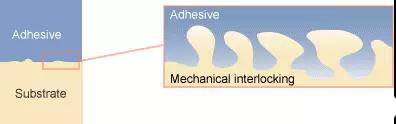

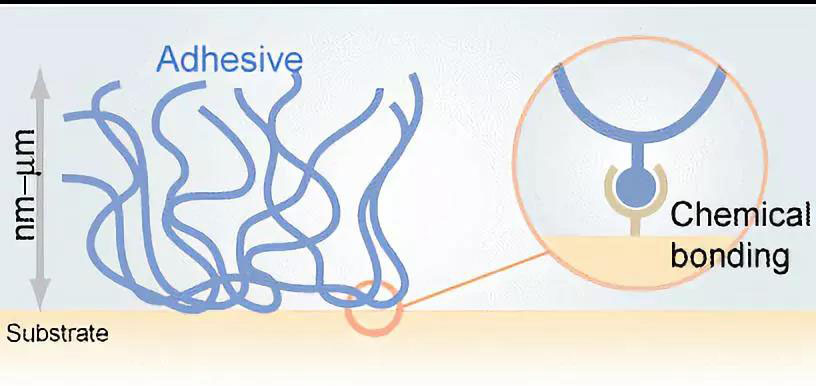

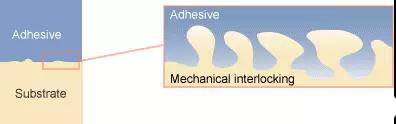

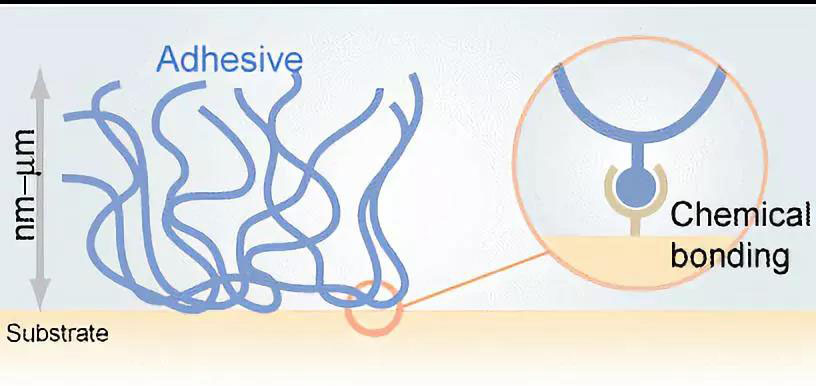

Mechanical and Chemical Mechanisms

物性及化学作用机理

Mechanical物性

Chemical化学

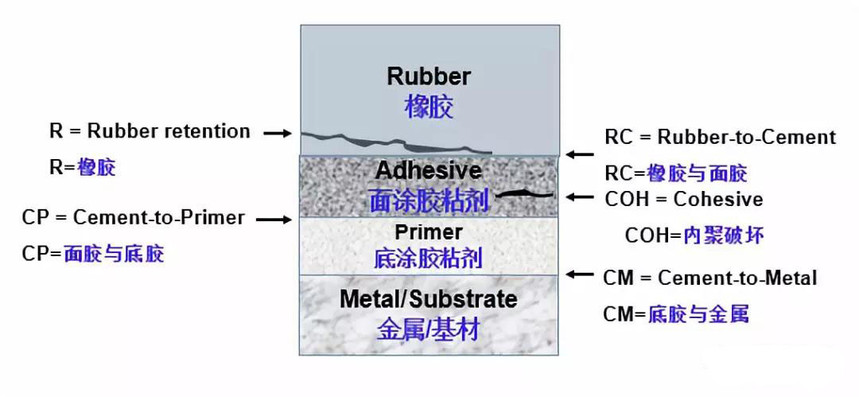

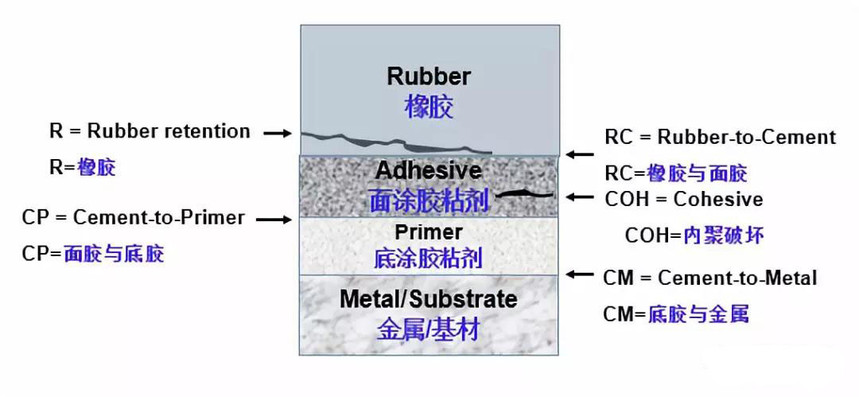

第二部分 粘结失效模式Bond Failure Modes

Methodsfor Troubleshooting Bond Failures

¨ Provide/definethe circumstances of the bond failure

定义粘结失效情况

¨ Inspect/determinefailure mode(s), location, amount

检测失效模式,位置,数量

¨ Reviewproduction materials and related processing

审核产品材料和相关工艺

¨ Create alist of potential causes

提出一系列潜在的因素

¨ Develop acorrective plan and test

提出改进的计划及测试

¨ Changematerial and/or process to verify cause(s)

根据影响因素更改材料或改进工艺

¨ Performonly one change at a time

每次只改变一个影响条件

BondFailure Modes of ASTM D429

ASTMD429定义的粘结失效模式

Cement-to-MetalFailure

CM失效模式

¨ Designatedas CM or M

CM或M的定义

¨ Primeror adhesive failure at the substrate interface

底涂或单涂胶粘剂与基材界面的粘结失效

¨ 25+%of failures in industry

在工业中占25%失效比例

¨ CommonCauses of Failure: Improper substrate preparation, improperhandling/application of Primer or Adhesive

典型的失效因素:不合适的基材处理,不正确的胶粘剂应用

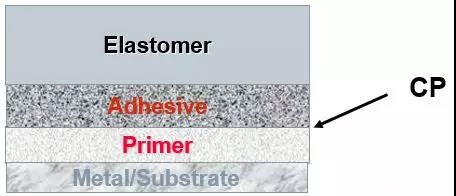

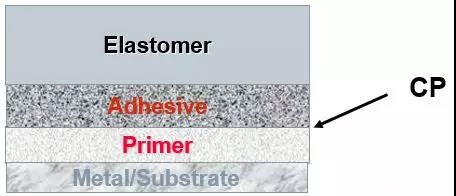

Cement-to-Primer Failure

CP失效模式

¨ Designatedas CP

CP的定义

¨ Cement= Adhesive

Cement =面涂胶粘剂

¨ Failureoccurs between primer and adhesive

失效发生与底涂与面涂胶粘剂间

¨ <10%of failures in industry

工业上发生概率<10%

¨ CommonCauses of Failure: Contaminated primer surface or improper handling/applicationof Primer or Adhesive, plasticizer migration from compound

典型的失效因素:底涂表面被污染或不正确的胶粘剂应用,增塑剂的迁移

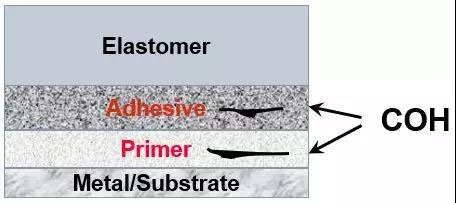

Cohesive Failure

胶粘剂内聚破坏

¨ Not aASTM type but failure occurs within either primer or adhesive layer

不是ASTM失效模式,但会在底涂或面涂胶粘剂层间发生

¨ Failureoccurs within either primer or adhesive layer

失效发生在胶粘剂的层间

¨ <5%of failures in industry

工业上发生概率<5%

¨ CommonCauses for Failure: Improper handling/application such as Primer or Adhesive istoo thick

典型的失效因素:不正确的胶粘剂应用或胶粘剂太厚

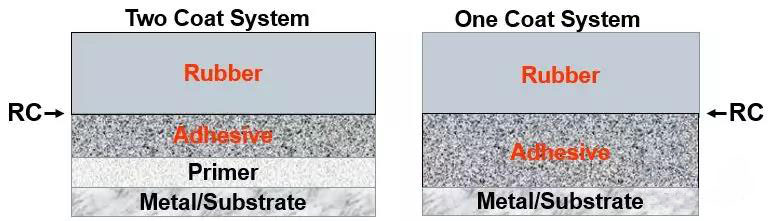

Rubber-to-CementFailure

RC失效模式

¨ Designatedas RC, cement = adhesive

RC失效定义,cement = 面涂胶粘剂

¨ Failureoccurs between rubber and adhesive

失效发生在橡胶与胶粘剂间

¨ Lookfor evidence of adhesive adhering to substrate, but not to rubber surface

胶粘剂与基材有良好的粘结,但是与橡胶表面粘结失效

¨ 50+%of failures in industry

工业上发生概率50+%

¨ CommonCauses of Failure: Adhesive applied too thin, improper mold cycle, bond-linestresses during de-mold, improper adhesive choice

典型的失效因素:胶粘剂太薄,不正确的硫化和脱模,胶粘剂选择错误

PartIII

ASTMD429 Bond Tests and Standards

ASTMD429粘结测试及标准

ASTMInternational

¨ ASTM isthe American Society for Testing and Materials

ASTM是美国对于测试及材料的标准

¨ Web site:www.astm.org

网址:www.astm.org

¨ CommitteeD-11 handles RTM bonding

D-11委员会执行RTM粘结

¨ ASTMmethods have been the standard for defining bond failure modes, lab andproduction testing and new product development for many years

ASTM已经成为定义粘结失效模式,实验室及产品测试,新产品开发的标准

¨ All testreport data reported with pull value and % rubber retention

所有的测试数据应记录拉伸强度和覆胶率

ASTM D429 Tests

ASTM D429 测试

¨ METHOD A: Button 扯离

¨ METHODB: Coupon 剥离

¨ METHODC: Conical 锥形扯离

¨ METHODD: Post Bond (PV bonding) 后硫化粘结测试

¨ METHODE: Rubber Lining 橡胶内衬测试

¨ METHODF: Buffer 弧面扯离

¨ METHOD G:Double Shear Cylindrical 双剪切测试

¨ METHOD H:Quadruple Shear 四面剪切测试

ASTMD429 Method B (Coupon)

¨ 45undefinedordm; or 90undefinedordm;peel, 2 inches (5 cm)/minute or 20 inches (50 cm)/minute, 45undefinedordm; peel preferreddue to shear angle

45undefinedordm; or 90undefinedordm;剥离,拉伸速度5CM或50CM每分钟,由于剪切角的原因, 45undefinedordm;剥离为首选

¨ Primaryand environmental tests

常规及耐环境测试

¨ Verydependent on tear and tensile strength of rubber

很大程度取决于橡胶的撕裂和拉伸强度

¨ Lowerdiscrimination than other test methods

相对于其他测试方法辨别力低

¨ Inexpensive,easy to coat and mold parts, quick feedback

便宜,方便涂胶和成型,快速反馈结果

¨ Compression,transfer and injection molding

模压,转移模,注塑成型

¨ Mostwidely used method for customer screening and our new product developments

广泛用于新产品开发和客户胶粘剂选型

ASTM429 Method C (Conical)

¨ Combination ofshear/tension

剪切/拉伸的结合

¨ Expensive inserts

标准件昂贵

¨ Time consuming,difficult to prepare and coat metal inserts

耗时久,表面处理及涂胶困难

¨ Good test for primeradhesion at the tip

对于顶端的底涂胶粘剂有良好的测试

¨ Transfer mold only

只用转移模成型

¨ Limited use due toexpense and time

由于费用及时间限制其使用

ASTM D429 Method D (Post Bond)

¨ Uses curedcompression set rubber

使用压缩变形放置橡胶

¨ Tensile test

拉伸测试

¨ Requires fixture jig(10% compression) to obtain bond-line pressure

需要固定夹套(10%压缩率)来得到粘结压力

¨ Compatible assemblyoil is used between adhesive and cured rubber

为方便装配可在胶粘剂和橡胶间使用专用装配油润滑

¨ Excellent, inexpensivetest for adhesion to cured rubber

对于硫化橡胶与胶粘剂是极好的,便宜的测试

ASTM D429 Method F (Buffer)

¨ Inexpensive tensiletest

便宜的拉伸实验

¨ Top surface isconvex, applies high shear force to primer at edges during pull test

在测试中表面的弧度给边缘的底涂胶粘剂以高的剪切力

¨ Good for primary orenvironmental tests

良好的常规或耐环境性测试

¨ Part can cycled infatigue testing (for example: 3 Hertz, 30% elongation for 1MM cycles)

零件可以在耐疲劳实验中循环使用(如:3Hz,30%延长率100万次疲劳实验)

¨ Transfer orinjection molding

转移模或注塑模成型

¨ *Preferred test ofmany Automotive applications

对于汽车应用零件是优选的测试方法

Part IV

Production Bond Test Methods

产品粘结测试方法

¨ Bondtests should be conducted per engineering specification for manufactured partsor customer’s special requirements:

测试应根据工程规范或客户特殊要求进行

¨ Fixturing for push or pull out or hand peel

推、拉、手工剥离应配备固定夹具

¨ Establish specification range: % rubber retention, 90%+is typical (plus load value from test machine), range depends upon material,bond surface area, type of force and speed of testing

确定规范:%橡胶保留,典型的附胶率为90+%(加上从测试仪器上得到的强度),规范的范围取决于材料,粘结表面,加载力的类型和测试速度

¨ Additional tests to include dynamic cycling, temperatureand fluid soaks, etc.

其他测试包括动态循环测试,高低温度和液体浸泡等

Production Bond Test Methods

¨ Establish bond test frequency: for example: 1 part permold cycle, 1 or 3 times per shift, etc.

确定粘接测试频率:如每模一个零件,每班次1-3个零件等

¨ Bond tests shouldcomplete separate the substrate from the rubber in the bonded region

测试应该将基材从的橡胶粘结区域完全分离开

¨ Most importantly,bond tests are a measurement of production quality and should prevent defectiveparts from reaching end customer

最重要的是,粘结测试是一种生产产品质量的检测方法,应防止有缺陷的产品流向最终客户

¨ Scrap rates aretypically maintained below 2%

典型的废品率应控制在<2%

¨ Periodic audits ofall processes are beneficial to ensure that processes are maintained withinproduction specifications

定期的对所有工艺的审核,将有利于工艺在产品生产规范中运行。